Prototype development is a critical phase in the product design process. However, it often comes with its fair share of hurdles. Addressing prototype development challenges effectively can significantly impact the success of the final product. This blog explores the common prototype problems faced during this phase and offers practical solutions to overcome prototyping issues and redefine the importance of the development of a software prototype before any project.

Key Challenges in Prototype Development

1. Lack of Clarity in Product Requirements

This can cause the entire prototyping process to derail. Without a clear vision, the prototype is rarely aligned with the planned design which causes a waste of resources and bearings.

Why This Happens:

- Different stakeholders could also have different views on what the product should be doing.

- Thus, the goals may be unrealistic because market research may be incomplete or misinterpreted.

- When things have to be adjusted quickly to keep up with competitors or respond to the market, the original objectives often become blurry.

Solution:

- Start with the process by holding detailed collaborative workshops with all stakeholders.

- Write down a detailed product requirement sheet that speaks about key features, performance benchmarks, and end users’ expectations.

- Keep this document up to date with frequent reviews and updates as the prototype grows.

2. Budget Constraints

Developing prototypes can be a costly endeavor, particularly for high-fidelity models that require advanced materials and testing. When we create a bad prototype, budget overruns are common, and unforeseeable iterations or surprises can make a challenging problem even more difficult to solve in the overall software product development.

Why This Happens:

- This often causes a lack of a clear roadmap resulting in several unnecessary iterations.

- Advanced tools or specialized expertise needed for complex designs can inflate costs.

- There may be a need for additional investment with regard to the testing and validation phases if initial results fail to generate the desired results.

Solution:

- Start with low-fidelity models to validate basic concepts before progressing to expensive high-fidelity versions.

- Leverage rapid prototyping solutions like 3D printing or digital simulation tools to reduce material waste and turnaround times.

- Create a contingency budget for unexpected changes and overs.

3. Technical Feasibility Issues

The reality — going from an idea to a product, from a concept to a prototype — often uncovers technical constraints. They include material inadequacies and design faults that render the prototype unworkable.

Why This Happens:

- In the conceptual phase of designing the designers may overlook practical constraints.

- If you don’t collaborate with the engineers and designers, the designs will be impractical.

- Emerging technologies or methods might not be mature enough to meet the needs expressed above.

Solution:

- In product design, you must perform a comprehensive feasibility study when you begin with prototyping to know what potential technical barriers you will encounter.

- Modular designs, make it easier to fine-tune specific components of a prototype without having to redo the entire prototype.

- Work with technical experts and use advanced tools already available to you such as CAD software to visualize and then test design concepts.

4. Inefficient Iteration Cycles

A major challenge of prototype development is the inefficiency in supporting the iterative processes. Poor management leads to feedback and redesign that stretches timelines and costs.

Why This Happens:

- Systematically gathering feedback does not exist, so revisions are often incomplete or unclear.

- However, teams may not have the tools or processes to quickly implement changes quickly.

- Communicating within large teams can be difficult resulting in delays in cycle iteration.

Solution:

- Implement agile development practices to streamline the iteration process, ensuring smaller, manageable updates.

- The use of project management tools and dedicated team augmentation assists in keeping track of the progress of the project, defining the task, and embodying the lessons learned for the benefit of the following projects.

- Make designs modular, so that certain features can be easily updated throughout the system quickly.

5. Material and Manufacturing Limitations

The choice of the right materials for your prototype can be arduous. Poor performance results from inappropriate materials, and manufacturing limitations constrain design choices.

Why This Happens:

- Lack of access to suitable materials may result in teams being forced to cut corners on quality.

- The prototype may have more complexity, or more intricate design than the manufacturing process can handle.

- The budget constraints may force the developers towards less effective materials.

Solution:

- Research till well till you can find materials that satisfy the functional and aesthetic requirements.

- Work with manufacturing specialists who know how to treat prototyping as a collaborative process.

- Try many material options at small scales before placing a large order.

6. Time Constraints

In competitive markets, especially when time is a critical factor in solving prototype development challenges, speed can either win the battle or lose the war. Entrepreneurs often find themselves within a tight deadline paradox, not being able to reach their desired quality while staying within deadlines.

Why This Happens:

- Blindly setting unrealistic delivery timelines.

- Delays can be caused by unanticipated challenges like design revisions or test failures.

- Without prioritization, it’s possible that teams could get stuck on secondary features over critical aspects.

Solution:

- Try to break the prototyping process down into smaller liveable phases that have achievable milestones.

- Track progress early and identify bottlenecks with tools like Gantt charts.

- First focus on making a functional prototype and leave secondary features for later, when you finish core goals.

Read More:- Why is MVP in Software Development necessary for Businesses in 2024?

Cost Analysis of Prototype Development

Oftentimes, prototyping occurs right alongside MVP development (Minimum Viable Product), or in other words, a detailed representation of the final product. Below is a regional cost breakdown for MVP development:

| Region | Hourly Rate ($) | Estimated Cost for MVP Development |

| United States | 100-150 | $50,000 – $100,000 |

| United Kingdom | 70-120 | $35,000 – $85,000 |

| India | 20-50 | $10,000 – $30,000 |

This cost varies significantly based on the complexity of the prototype, the materials used, and the expertise required.

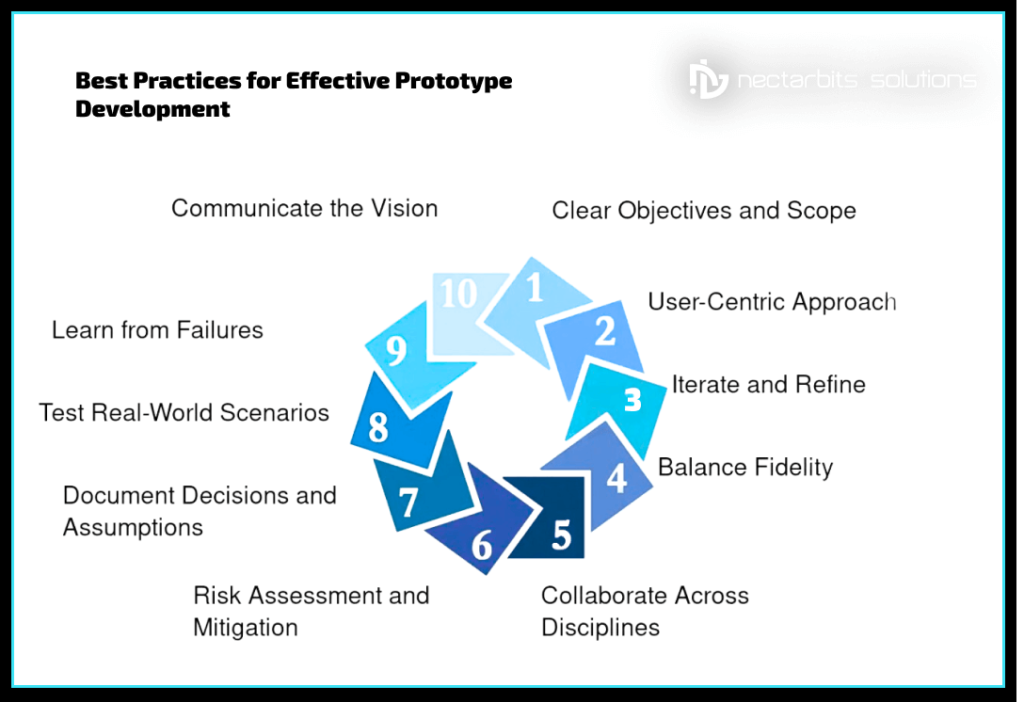

Conclusion

Product prototyping is an essential step in product development, but has its challenges too. Businesses can save time, and money and improve the quality of the final product by identifying and solving problems of prototype development. If strategies are adopted such as modular designs, rapid prototyping solutions, and a series of verifying feasibility studies, prototyping is going to be much smoother and beneficial. In the long run for the company, partnering with a professional MVP development company like Nectarbits can help create a fully fledged MVP to better define its upcoming full-cycle software development delivery strategies.

Frequently Asked Questions (FAQs)

1. What are the most common prototype development challenges?

Prototype development often faces hurdles like unclear product requirements, budget constraints, technical limitations, and inefficient iteration cycles. These challenges arise due to poor planning, lack of collaboration, or unexpected market shifts.

How to tackle them:

- Define clear product requirements through stakeholder workshops.

- Start with low-fidelity models to manage costs.

- Use modular designs for flexibility during iterations.

2. How can I address budget constraints in prototyping?

Budget constraints are a significant prototype development challenge, especially for high-fidelity designs requiring advanced tools and materials. Overruns often occur due to undefined scopes and repeated iterations.

Solutions include:

- Validate designs with cost-effective models first.

- Leverage rapid prototyping solutions like 3D printing.

- Allocate contingency funds for unforeseen adjustments.

3. What is the role of rapid prototyping in overcoming technical hurdles?

Rapid prototyping allows teams to quickly test and refine designs, addressing technical issues that emerge during development. It bridges the gap between concept and functionality effectively.

Benefits include:

- Faster iteration cycles for feedback implementation.

- Lower material waste with digital simulation tools.

- Early detection of design flaws, saving time and costs.

4. How can teams streamline prototype iteration cycles?

Prototype iteration difficulties often stem from mismanaged feedback and lack of communication. Efficient iteration cycles are crucial for refining designs without wasting time.

To improve cycles:

- Implement agile practices for smaller, focused updates.

- Use project management tools to track tasks and centralize feedback.

- Encourage cross-team collaboration to ensure smooth iterations.

5. What strategies help overcome material and manufacturing limitations?

Material and manufacturing challenges arise due to restricted access to suitable materials or incompatible processes for complex designs. These can compromise quality and functionality.

Effective strategies:

- Research material properties to match requirements.

- Partner with manufacturing experts for tailored solutions.

- Test materials in small batches before scaling up production.