Quick Summary

AI-powered predictive maintenance is transforming fuel delivery fleets by continuously monitoring high-failure components, including PTOs, pumps, meters, hoses, and vehicle engines. With modern fuel truck maintenance software, fleets can reduce unplanned downtime by up to 35%, lower repair costs, improve safety and compliance, and maintain higher on-time delivery rates, thereby turning proactive maintenance into a clear operational advantage.

Fuel delivery fleets operate under strict uptime, safety, and compliance demands where even a single failure, whether in the engine, PTO, pump, meter, or hose. can disrupt routes and break customer SLAs. Traditional approaches can’t keep pace with today’s operational pressures.

Predictive maintenance changes this by moving fleets from reactive → preventive → predictive, using real-time sensor data, AI insights, and modern fuel truck maintenance software to detect issues before they cause downtime.

Many companies now invest in custom fuel delivery apps built with advanced telematics and smart maintenance modules, like those developed at NectarBits, to modernize monitoring, automate alerts, and streamline decision-making.

Predictive maintenance is no longer optional; it’s the foundation for safer, more reliable, and SLA-driven fuel delivery operations.

Industry Statistics That Show Predictive Maintenance Is No Longer Optional

Predictive maintenance is no longer a “nice-to-have” for fuel delivery fleets; it is becoming a core operational requirement. Multiple industry studies highlight how AI-driven monitoring and telematics drastically improve reliability, safety, and cost efficiency across modern fleets.

Key Industry Statistics

- 35–45% reduction in unplanned downtime

Real-time health monitoring helps detect PTO vibration anomalies, pump pressure drops, injector issues, and hose degradation before they lead to on-route failures. - 10–25% reduction in overall maintenance costs

Fleets shift from expensive emergency repairs to planned maintenance, with optimized parts ordering and reduced technician labor waste. - 8–12% improvement in fuel efficiency

AI models identify engine issues early, clogged filters, failing injectors, and tire pressure deviations, helping fuel delivery fleets lower operating costs per mile. - 50%+ increase in equipment lifespan

PTOs, high-pressure pumps, digital meters, hoses, and injectors last significantly longer when monitored continuously, reducing replacement costs and extending the return on the asset lifecycle. (Source:- uptake.com)

What Is Predictive Maintenance? (Layman + Technical Explanation)

Predictive maintenance is a data-driven maintenance strategy that uses real-time sensors, telematics, and AI models to identify early signs of equipment failure before downtime occurs. Instead of repairing parts after they break or relying on fixed service schedules, the system continuously evaluates the actual health of every critical component on a fuel truck.

Layman’s Explanation

Think of predictive maintenance as a “health monitoring system” for your fuel trucks.

Just like a smartwatch tracks heart rate and alerts you when something is wrong, predictive maintenance tracks how your truck and pumping equipment behave — vibration, pressure, temperature, flow, torque, and more.

Unlike:

- Reactive maintenance (fix after failure)

- Preventive maintenance (fix on a schedule)

Predictive maintenance tells you exactly when a part is starting to wear out, long before it causes a breakdown. This means fewer surprises, fewer route failures, and fewer emergency repair bills.

Technical Explanation

Predictive maintenance uses a combination of:

- IoT sensors tracking pump pressure, PTO vibration, hose integrity, meter flow consistency, engine temperature, injector firing patterns, etc.

- Telematics + CAN bus data reading fault codes, RPM anomalies, DPF health, engine load, idle behavior, and OBD diagnostics.

- AI/ML algorithms compare real-time data with historical patterns to detect abnormalities.

- Predictive models calculating Remaining Useful Life (RUL) for components.

- Automated alerts are sent to mechanics, dispatchers, or fleet managers when a component deviates from normal performance.

The result is a precise, proactive maintenance strategy based on evidence, not assumptions.

Why Predictive Maintenance Matters for Fuel Delivery Fleets

Fuel trucks are more complicated than standard logistics vehicles. They rely on a combination of mechanical and pumping systems to complete a delivery. If any one of these components fails, the entire route fails.

Predictive maintenance is uniquely valuable because it monitors both:

Vehicle Components

- Engine and injectors

- Transmission and drivetrain

- Brake system

- Electrical system

Fuel-Delivery Components (Mission-Critical)

- PTO (Power Take-Off) units:

Vibration, torque, and temperature monitoring help detect shaft misalignment, bearing degradation, and lubrication failures. - Tanker pumps & compressor motors:

AI identifies pressure drops, rising current draw, impeller drag, and early cavitation symptoms before pumps seize. - Flow meters:

Flow consistency and calibration drift alerts prevent measurement inaccuracies and delivery disputes. - Hoses, seals & nozzles:

Pressure and leak-detection sensors help prevent spills, contamination, and safety violations.

Predictive maintenance ensures that the truck and the pumping equipment work flawlessly — making every delivery safer, faster, and more reliable.

How Predictive Maintenance Works

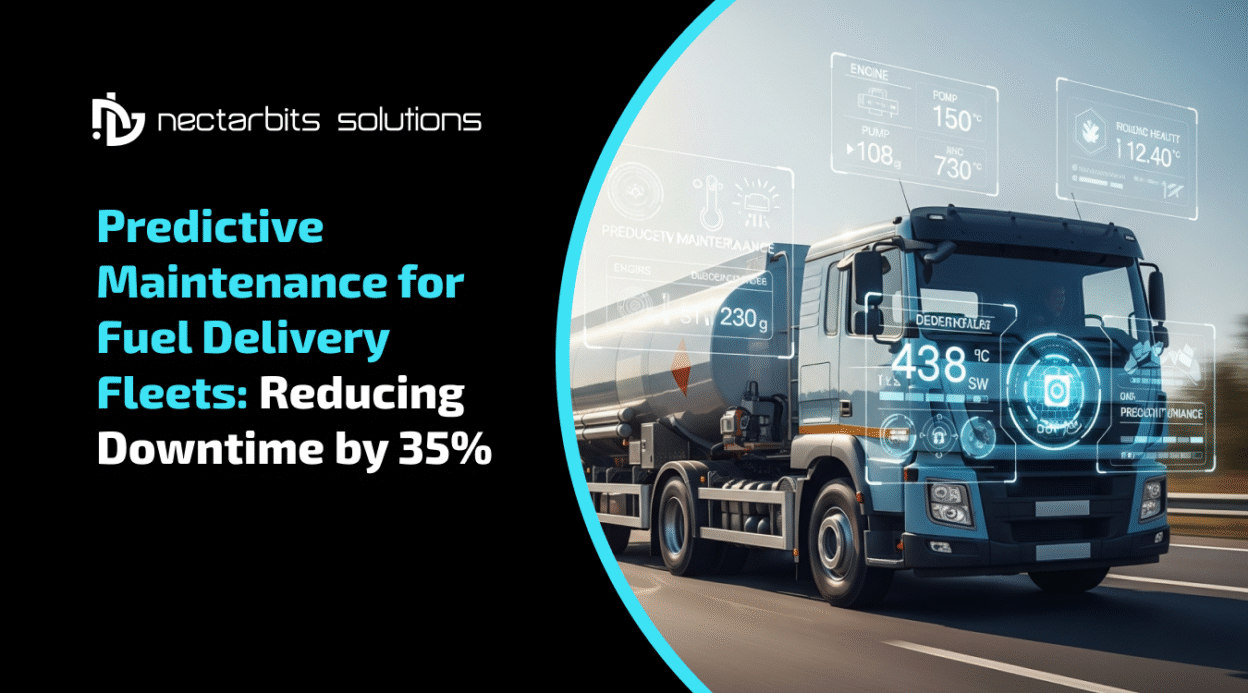

Predictive maintenance helps fuel fleets avoid breakdowns by using real-time data, AI, and automated workflows. Instead of waiting for a failure, the system predicts issues before they happen and triggers the right action at the right time. Here’s how the process works in three simple layers:

1. Data Collection: The Sensors Doing the Heavy Lifting

Fuel trucks generate thousands of data points every minute. Predictive maintenance begins by capturing them through:

- Telematics units (GPS, idle tracking, engine health)

- IoT sensors mounted on trucks, pumps, and tanks

- OBD-II / CAN bus diagnostics reading error codes and performance metrics

- Fuel-fleet–specific hardware like:

- Pump temperature & pressure sensors

- Nozzle cycle counters

- Tank-level & spill-prevention sensors

- PTO engine activity monitors

This gives your system a complete, real-time picture of each truck’s operational health.

2. Data Processing & Analytics: Turning Raw Data Into Insights

Once captured, all sensor and telematics data goes through an analytics layer powered by AI/ML:

- Machine learning models identify patterns in usage, wear, and stress.

- Anomaly detection catches unusual behavior early (e.g., pump overheating, tank pressure variations).

- Predictive scoring ranks each vehicle by failure risk so you know which truck needs attention first.

This transforms basic readings into actionable insights—critical for safety-heavy operations like mobile fueling and custom fuel delivery apps.

3. Action Layer: Automated Alerts & Maintenance Execution

This is where insights turn into action. The system automatically triggers:

- Alerts to drivers (e.g., “reduce load pressure”)

- Alerts to mechanics (e.g., “pump bearing failure predicted”)

- Alerts to dispatchers (e.g., “schedule replacement truck for tomorrow’s route”)

These alerts seamlessly integrate with:

- Your fleet dashboard

- Work order management

- Fuel truck maintenance software

- Any custom-built fuel delivery platform

For companies building or upgrading their digital ecosystem, these workflows can be embedded inside your fueling platform—learn more via our internal page on On-Demand App Development.

Key Benefits for Fuel Delivery Fleets

Predictive maintenance delivers measurable operational, financial, and safety advantages for fuel distributors. Unlike generic fleet tools, it directly addresses the stress, risk, and compliance demands of fuel trucks, PTO-driven pumps, meters, hoses, and HAZMAT transport. When paired with a modern SaaS solution for predictive maintenance, these benefits become scalable across the entire fleet.

Maximum Uptime & Operational Reliability

Fuel delivery fleets face strict SLAs where even one truck going down can disrupt multiple customer routes. Predictive maintenance continuously monitors engine health, PTO load, pump temperature, pressure levels, vibration signatures, tire health, and telematics data—allowing the system to flag failures before they cause downtime.

Result: Fleets reduce unplanned breakdowns by 30–45%, keep trucks mission-ready, and stabilize daily delivery schedules.

Significant Reduction in Repair & Lifecycle Costs

Emergency repairs are 3–5× more expensive than planned maintenance. By forecasting component wear (injectors, PTO shafts, pump bearings, brake rotors, etc.), fleets avoid catastrophic damage and switch to scheduled repairs.

Savings Areas:

- Reduced tow charges

- Lower labor hours

- Avoided after-hours/emergency repairs

- Fewer replacement parts

- Less vehicle idle time

Overall, this cuts total maintenance costs by 10–25%.

Extended Lifespan for Trucks & Fuel-Handling Equipment

Fuel delivery equipment works under intense stress—continuous PTO operation, pump cycles, pressure variations, and temperature fluctuations. Predictive analytics ensures that engines and pump systems operate within safe parameters.

Impact:

- 30–50% longer lifespan for PTOs, pumps & metering systems

- Longer engine life due to stabilized load & temperature

- Better preservation of hoses, seals & valves

This reduces capital expenditure on new trucks and specialized equipment.

Higher SLA Performance & Contract Reliability

Fuel suppliers must maintain strict delivery windows for industrial fleets, construction clients, marine operations, or commercial gas stations. Predictive maintenance prevents route failures caused by mid-day breakdowns.

Benefits:

- SLA compliance increases by 10–18%

- Fewer missed or late deliveries

- Stronger customer trust and contract renewals

For contract-driven businesses, reliability directly translates into revenue retention.

Enhanced Driver Safety & Road Risk Reduction

Fuel trucks carry hazardous materials, making equipment failures a major safety risk. Predictive maintenance identifies early signs of brake wear, overheating pumps, fuel leaks, compressor failures, or abnormal vibrations.

Outcome:

- Fewer roadside failures

- Lower incident rates

- Reduced driver stress

- Lower insurance claims

This strengthens the overall safety culture of the fleet.

Streamlined Compliance for DOT, HAZMAT & Environmental Standards

Fuel trucks fall under strict regulatory requirements. Predictive systems help fleets maintain always-ready compliance by:

- Auto-generating digital inspection logs

- Monitoring critical components linked to HAZMAT regulations

- Detecting emission-related issues early

This makes audits easier and avoids violations or penalties.

Better Fuel Efficiency & Lower Operating Costs

When engines operate under optimal conditions, fleets save fuel. Predictive maintenance catches issues that silently increase fuel consumption, such as:

- Clogged injectors

- Turbo issues

- Pump drag

- Low tire pressure

- Misfires

Typical improvement: 8–12% better MPG across a fleet.

For high-mileage fuel delivery trucks, this represents substantial annual savings.

Stronger Asset Utilization & Productivity

More reliable trucks mean more deliveries per day. Predictive systems reduce the time trucks spend in the shop, enabling dispatchers to plan routes with confidence.

Fleet Impact:

- Higher driver productivity

- Increased daily fuel volume delivered

- Optimized allocation of backup trucks

Predictive Maintenance vs Reactive vs Preventive Maintenance

Fuel delivery fleets operate under extreme pressure — hazardous materials, strict SLAs, PTO-driven pumps, and continuous engine load. The maintenance strategy you choose directly impacts uptime, safety, compliance, and customer trust. Below is a concise yet powerful comparison that shows why predictive maintenance is now the benchmark for high-performance fuel fleets.

Maintenance Strategy Comparison Table

| Maintenance Type | How It Works | Pros | Cons | Impact on Fuel Delivery Fleets |

| Reactive Maintenance | Fixing a truck after it breaks down. | Low upfront cost; simple to manage. | Highest repair cost; major downtime; safety risks. | Causes route failures, missed SLAs, pump failures, and expensive roadside emergencies. |

| Preventive Maintenance | Scheduled service at fixed intervals (mileage, engine hours). | Predictable; reduces some breakdowns. | Over-servicing doesn’t detect hidden issues; it still leads to surprise failures. | Better than reactive, but blind to PTO stress, pump overheating, injector wear, or vibration anomalies. |

| Predictive Maintenance (AI-Driven) | Real-time monitoring with sensors + analytics to predict failures before they happen. | Highest uptime; lowest repair and fuel cost; better safety and compliance; maximum asset life. | Requires sensors & software; initial setup. | Reduces downtime by 30–45%; improves SLA performance; protects pumps/meters/PTOs; prevents costly HAZMAT incidents. |

Why Predictive Maintenance Is the Clear Winner for Fuel Fleets

Fuel delivery trucks are mission-critical assets, and any breakdown triggers cascading problems:

- Missed deliveries → dissatisfied clients

- High emergency repair bills

- Delays in commercial fueling schedules

- Safety hazards during roadside failures

- Potential HAZMAT compliance violations

Predictive maintenance eliminates these risks by detecting early signs of failure in:

- PTO shafts & pump motors

- Fuel metering systems

- Engine injectors & turbo systems

- Brake, tire, and suspension components

- Hose pressure and temperature variations

Unlike reactive or preventive approaches, predictive maintenance continuously learns from sensor patterns, telematics data, and historical failures, becoming more accurate over time.

For fleets that cannot afford downtime, AI-powered predictive maintenance is no longer optional. It is the standard for maximum uptime, safer operations, better SLAs, and improved profitability.

Want to go deeper into fleet automation?

Read our detailed breakdown on how smart fueling platforms are built in our Fuel Delivery App Case Study.

Core Features of Predictive Maintenance for Fuel Delivery Fleets

Predictive maintenance combines IoT sensors, AI analytics, and maintenance workflows to keep fuel trucks and their pumping systems operating reliably. Instead of reacting to failures, fleets gain continuous visibility into engine health, PTO condition, pump performance, and meter accuracy — enabling smarter decisions and higher uptime.

- Real-Time Monitoring (Engines + Fuel-Delivery Hardware)

Predictive systems collect continuous data from:

- PTO shaft vibration

- Pump motor temperature & pressure

- Fuel meter accuracy

- Tanker pump flow rates

- Engine diagnostics (injectors, turbo, coolant temp, oil pressure)

- Brake & tire condition

This enables fleets to catch abnormalities hours or days before they cause a breakdown or delivery shutdown.

- Component Failure Prediction

Machine learning models analyze historical failures, sensor patterns, and telematics data to estimate when a component is likely to fail. Whether it’s a pump starting to overheat or a PTO showing early vibration anomalies, the system warns maintenance teams well in advance — allowing repairs to happen without disrupting customer schedules.

- Automated Maintenance Scheduling

Instead of relying on fixed intervals, predictive platforms automatically update maintenance schedules based on real-world vehicle usage. This ensures vehicles are neither over-serviced nor neglected, while workshop teams know exactly what needs attention.

At this stage, many fleets also integrate a mobile app for fleet maintenance tracking, enabling technicians and drivers to receive alerts, log issues, and update service records directly from the field.

- Parts Inventory Optimization

Many fuel fleets overstock expensive components like pumps, injectors, meters, and PTO assemblies due to unpredictable failures.

Predictive maintenance solves this by:

- Forecasting which parts will fail soon

- Alerting procurement teams

- Reducing warehouse costs

- Ensuring the right part is always available

This eliminates emergency ordering and cuts inventory costs by 10–15%.

- Driver Mobile Alerts

Drivers receive simple, actionable mobile alerts when something needs attention — such as tire pressure drops, pump overheating, or unexpected engine codes. This removes guesswork and transforms drivers into proactive partners in fleet uptime, improving safety and reducing roadside breakdowns.

- Workshop Dashboards

Maintenance supervisors get a complete, real-time picture of fleet health: current vehicle condition, predicted failures, upcoming service needs, and required parts. Instead of firefighting breakdowns, workshops can plan with confidence, reducing stress and improving technician efficiency.

- Seamless Integrations With Fleet Systems

Predictive maintenance becomes exponentially more powerful when connected to dispatching, routing, and fuel delivery software. If a vehicle shows a high-risk alert, the system can instantly update delivery assignments, reroute loads, or schedule workshop time automatically. Integrating with custom fuel delivery fleet software ensures maintenance, operations, and dispatch work as one coordinated ecosystem.

Best Practices to Implement Predictive Maintenance Successfully

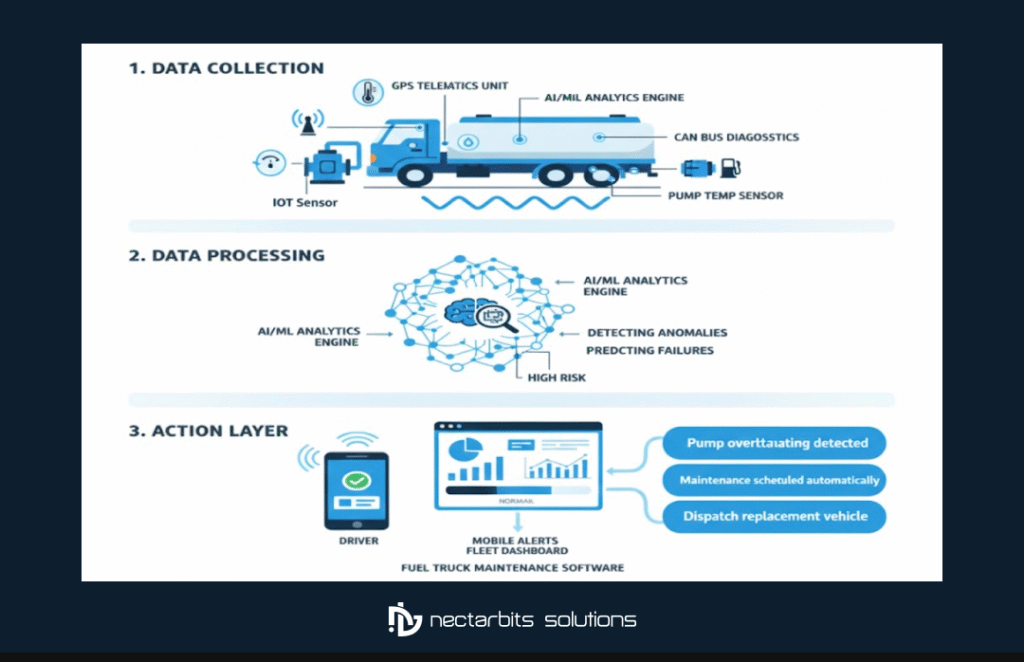

Predictive maintenance delivers real ROI only when it’s rolled out with a structured approach. For fuel delivery fleets handling hazardous materials, the implementation must be strategic, data-driven, and aligned with daily operations. These best practices ensure the transition is smooth and the benefits are immediate.

1. Start with a Pilot Fleet

Begin with 5–10 trucks to validate the technology, understand sensor behavior, and compare performance against non-pilot vehicles. A pilot helps your team fine-tune alerts, verify data accuracy, and build confidence before scaling across the entire fleet.

2. Identify High-Risk Components First

Fuel fleets should prioritize equipment that directly affects pump performance and safe delivery, such as:

- PTO shafts

- Fuel pumps and motors

- Hoses and nozzles

- Meters and pressure valves

- Brake systems

By focusing on these mission-critical parts, fleets see uptime gains faster and reduce the most expensive failures first.

3. Integrate Telematics + Mobile Apps

Predictive maintenance works best when telematics data and driver inputs flow into a single system.

Integrations should include:

- IoT sensors and CAN bus data

- Driver mobile apps for reporting anomalies

- Fuel delivery fleet software for dispatch & routing

- Workshop management tools

This creates a connected ecosystem where maintenance, drivers, and dispatchers work from the same real-time data.

4. Train Mechanics & Drivers Together

Predictive maintenance changes how teams work. Mechanics learn how to interpret predictive alerts and plan repairs proactively. Drivers learn how to respond to warnings, log issues quickly, and help feed data back into the system. This reduces resistance and boosts the accuracy of field reporting overall.

5. Establish a Central Maintenance Command Center

A dedicated dashboard for your maintenance supervisors transforms the workflow:

- Real-time vehicle health

- Alerts and predicted failures

- Work order automation

- Required parts & technician assignments

This central hub allows managers to shift from reactive firefighting to strategic, planned maintenance operations.

6. Track the Right KPIs (Not Just Downtime)

To measure success, fleets should track:

- MTTR (Mean Time to Repair)

- MTBF (Mean Time Between Failures)

- Downtime Hours per Truck

- Cost per Mile

- Parts Consumption Rate

- Pump/PTO failure frequency

These KPIs provide a clear before-and-after comparison, helping build a strong internal business case for ongoing predictive maintenance investment.

ROI & Business Impact of Predictive Maintenance for Fuel Delivery Fleets

Predictive maintenance delivers one of the strongest ROI multipliers in the fuel logistics industry because it targets the biggest cost leaks—unplanned downtime, emergency repairs, and safety-related disruptions. For operators managing hazardous materials and strict delivery windows, predictive maintenance for fuel delivery fleets ensures that trucks, pumps, PTO systems, and metering equipment stay road-ready with fewer surprises.

By shifting from reactive fixes or rigid time-based service to data-driven maintenance, fleets repair only what’s needed, at the right moment. This leads to more deliveries per truck each day, fewer penalties for late arrivals, and significantly lower emergency repair bills. The safety upside is just as powerful: fewer roadside breakdowns, reduced accident exposure, and stronger compliance scores, which together help lower insurance costs over time.

However, the biggest impact appears when fleets quantify the financial benefit. Here’s a simple, practical framework to help teams build a solid internal business case:

But the real value comes when fleet operators quantify the savings. Below is a simple, practical ROI framework you can use to build a strong internal business case.

Simple ROI Framework: Build Your Predictive Maintenance Business Case

Step 1: Calculate Your Current Cost of Downtime

Every hour a fuel truck is off the road costs money. Use this formula:

Downtime Cost Per Hour = Lost Revenue per Hour + Driver Wage per Hour + Late Delivery Penalties

This establishes your baseline and shows how expensive reactive maintenance truly is.

Step 2: Estimate Your Annual Savings

Predictive maintenance reduces downtime by up to 35% across fleet operations. Apply that to your fleet:

Annual Savings = Downtime Cost per Hour × Annual Downtime Hours × 0.35

This gives you a clear, data-backed estimate of yearly cost reduction.

Step 3: Add Additional, Often Overlooked Savings

Predictive maintenance doesn’t just prevent breakdowns—it optimizes the entire lifecycle of your assets:

- Improved fuel efficiency through better engine health

- Longer component life, thanks to timely replacements

- Lower insurance premiums, driven by fewer incidents

- More on-time deliveries, increasing customer satisfaction, and retention

When combined, these savings often exceed the direct downtime reduction, delivering a 2–5x return on investment within the first year.

Challenges of Predictive Maintenance & How Fuel Fleets Can Overcome Them

While predictive maintenance delivers major ROI, deploying it inside a fuel delivery environment comes with unique operational challenges. The good news? Each issue has a proven, practical workaround, especially for fleets aiming to build a premium fuel delivery fleet maintenance ecosystem

1. Sensor Calibration & Hardware Reliability

Predictive models are only as accurate as the data they receive. If telematics sensors, engine probes, or tire pressure monitors aren’t calibrated correctly, insights become unreliable. Fleets can avoid this by scheduling routine sensor checks, using OEM-certified hardware, and setting automated alerts when a device goes offline or produces abnormal readings.

2. Data Quality & Inconsistent Inputs

Dirty, incomplete, or inconsistent data is one of the biggest blockers to prediction accuracy. To fix this, fleets should standardize data formats across vehicles, automate data ingestion from telematics devices, and use anomaly-detection tools to flag corrupted or missing data before it affects the model.

3. Technician & Driver Training Gaps

Even with the best system, predictive maintenance fails when teams don’t understand the workflows. Mechanics need to know how to interpret alerts, prioritize jobs, and update maintenance logs digitally. Drivers should understand warning indicators and how to report anomalies. Hands-on training, simple SOPs, and in-app guidance help bridge this gap quickly.

4. Integration With Dispatch, Routing & ERP Systems

Most fleets rely on multiple platforms—dispatch systems, route optimization tools, fuel delivery apps, and ERP software. Predictive maintenance must plug into all of them to provide value. Using open APIs, fleet management middleware, or a unified maintenance hub ensures data flows smoothly across the tech stack, reducing manual work and eliminating blind spots.

Future Trends in Predictive Maintenance for Fuel Delivery Fleets

Predictive maintenance is moving far beyond simple sensor alerts. Over the next 3–5 years, fuel fleets will see a shift toward intelligent, self-optimizing maintenance systems that reduce downtime to near zero. Here are the trends shaping the future:

1. Digital Twins of Fuel Trucks & Pumping Systems

OEMs and fleet-tech companies are increasingly building digital twins—virtual replicas of engines, PTO units, pumps, tank sensors, and flow meters.

These models simulate heat levels, vibration patterns, hydraulic pressure, fuel pump behavior, and load conditions to predict failures before they happen.

For fuel fleets, digital twins will allow:

- Real-time simulation of pump wear

- Predictive PTO clutch failure alerts

- Forecasting injector degradation

- Optimized maintenance intervals based on “virtual aging”

2. Edge AI Running Directly Inside Vehicles

Instead of sending all sensor data to the cloud, edge AI processes information right inside the truck’s telematics unit or ECU.

This reduces latency and makes predictions instant—even in low-network zones.

For fuel trucks, edge AI will enable:

- On-board PTO temperature anomaly detection

- Real-time pump vibration scoring

- Instant engine health predictions (without waiting for cloud sync)

- Faster safety decision-making for hazardous-material operations

3. Autonomous Maintenance Requests & Self-Triggering Work Orders

Fleets are moving toward vehicles that request their own maintenance.

When the system predicts an issue—like pump seal wear or injector imbalance—the truck will automatically:

- Generate a maintenance ticket

- Send the request to the nearest workshop

- Order required parts from inventory

- Schedule downtime around delivery commitments

This eliminates human delay and reduces breakdown probability dramatically.

4. OEM-Level Predictive APIs & Factory-Installed Health Systems

Major OEMs (Volvo, Daimler, Paccar, Ford Pro, Freightliner) are already offering factory-built predictive maintenance APIs.

Fuel fleets will soon receive:

- Pump & PTO health diagnostics directly from manufacturers

- Predictive engine service recommendations synced to warranty plans

- Integrated telematics + maintenance dashboards without third-party hardware

- Standardized data streams for easier integration with fuel delivery apps and ERPs

Want to dive deeper into modern fuel delivery fleet innovations? Explore the PetroApp Business Model with NFC Smart Chip Technology →

Conclusion: Predictive Maintenance Is Now a Competitive Advantage

Predictive maintenance has shifted from a “nice-to-have” to a core operational strategy for fuel delivery fleets. With tighter SLAs, rising compliance pressure, and the cost of unplanned breakdowns increasing every year, fleets that adopt AI-driven maintenance gain a clear edge—higher uptime, lower repair costs, safer operations, and more dependable deliveries.

Fuel delivery companies investing in this technology today are building fleets that are smarter, more efficient, and future-proof. Whether you operate 5 trucks or 500, predictive maintenance can immediately transform your performance metrics and long-term profitability.

If you’re planning to modernize your operations with integrated telematics, predictive analytics, and custom mobile tools, explore our Fuel Delivery App Development solutions and Fleet SaaS Development Services to build a truly connected and intelligent fleet.

FAQs:

1. How does predictive maintenance actually reduce downtime for fuel trucks?

Predictive maintenance uses IoT sensors, telematics, and AI models to detect early signs of component failure — especially on PTOs, pumps, injectors, hoses, and meters. By catching anomalies before they escalate, fleets prevent unexpected breakdowns, reduce roadside failures, and maintain higher delivery uptime.

2. Is predictive maintenance expensive to implement for small or mid-size fuel fleets?

Not anymore. Modern fuel truck maintenance platforms can integrate with existing telematics devices (Geotab, Samsara, Fleet Complete), meaning fleets avoid heavy hardware investments. Most solutions run on a subscription model, making it affordable even for fleets with 5–25 trucks.

3. What data is needed to make predictive maintenance work effectively?

The most important data points include engine temperature, oil quality, hydraulic pressure, vibration signatures, PTO load, fuel pump RPM, brake wear, and DTC (diagnostic trouble codes). Combining these with driver behavior and route conditions helps AI models predict failures with high accuracy.

4. Can predictive maintenance integrate with my existing fuel delivery app or dispatch system?

Yes. Modern solutions offer APIs that connect to routing systems, dispatch dashboards, ERP platforms, and custom fuel delivery apps. This ensures maintenance alerts flow directly to dispatchers, mechanics, and drivers — improving coordination across your entire operation.