Fuel delivery operators face an unrelenting challenge: razor-thin profit margins in an industry where operational costs continue to rise. The average fuel delivery company operates on margins of just 3–8%, with operational costs consuming 92–97% of revenue. Industry research from the American Transportation Research Institute (ATRI) highlights how rising operating expenses and low freight rates are severely squeezing trucking and fuel delivery profitability, reinforcing the urgency for operational efficiency improvements.

In this high-volume, low-margin business, even small percentage improvements in operational efficiency, such as fuel delivery, can mean the difference between profitability and bankruptcy.

The pressure intensifies as costs rise across every category. Statista reports that commercial fuel costs increased 23% year-over-year, labor costs rose 15%, and insurance premiums climbed 18%, reflecting the growing cost burden on transportation and fuel delivery operators. (Source: fleetowner.com)

For fuel delivery business owners, these numbers aren’t abstract statistics—they’re existential threats to survival. Yet technology offers a powerful counterforce. Companies implementing comprehensive tech-driven solutions reduce fuel delivery costs by 35-45% within the first 18 months while simultaneously improving service quality and customer satisfaction. This isn’t future potential; it’s present reality for forward-thinking operators who recognize that operational efficiency, fuel delivery, depends on intelligent automation, real-time data, and integrated digital platforms.

This guide reveals actionable, proven strategies to reduce fuel delivery costs across every operational category, with specific technologies, implementation roadmaps, and ROI projections that deliver results in months, not years.

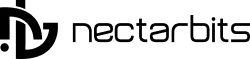

Understanding the Operational Cost Structure

Where Every Dollar Goes: Breaking Down Fuel Delivery Costs

To effectively reduce fuel delivery costs, you must first understand your cost structure:

| Cost Category | % of Total Operating Cost | Annual Cost (Medium Operation) | Cost Reduction Potential |

| Fuel and Vehicle Operating Costs | 35-42% | $350,000 – $420,000 | 18-28% savings possible |

| Labor and Driver Wages | 28-35% | $280,000 – $350,000 | 12-22% savings possible |

| Vehicle Maintenance and Repairs | 12-18% | $120,000 – $180,000 | 25-40% savings possible |

| Insurance and Liability | 8-12% | $80,000 – $120,000 | 10-20% savings possible |

| Administrative and Overhead | 6-10% | $60,000 – $100,000 | 40-60% savings possible |

| Technology and Communications | 2-4% | $20,000 – $40,000 | -50% (investment increases initially) |

| Compliance and Regulatory | 2-3% | $20,000 – $30,000 | 15-25% savings possible |

Key Insight: While fuel and labor represent the largest cost categories in absolute terms, administrative overhead and maintenance offer the highest percentage reduction potential through technology, delivering quick wins that fund larger transformation initiatives.

The Cumulative Impact of Small Inefficiencies

Small operational inefficiencies compound rapidly in fuel delivery:

Example Scenario – 10 Vehicle Fleet:

- 5% excess route mileage = $87,500 annual waste

- 10% administrative inefficiency = $42,000 annual waste

- 15% preventable maintenance issues = $27,000 annual waste

- 8% delivery scheduling inefficiency = $56,000 annual waste

- Total Waste: $212,500 annually (21% of $1M operating budget)

Technology that reduces fuel delivery costs by capturing these inefficiencies generates immediate, measurable ROI while creating sustainable competitive advantages.

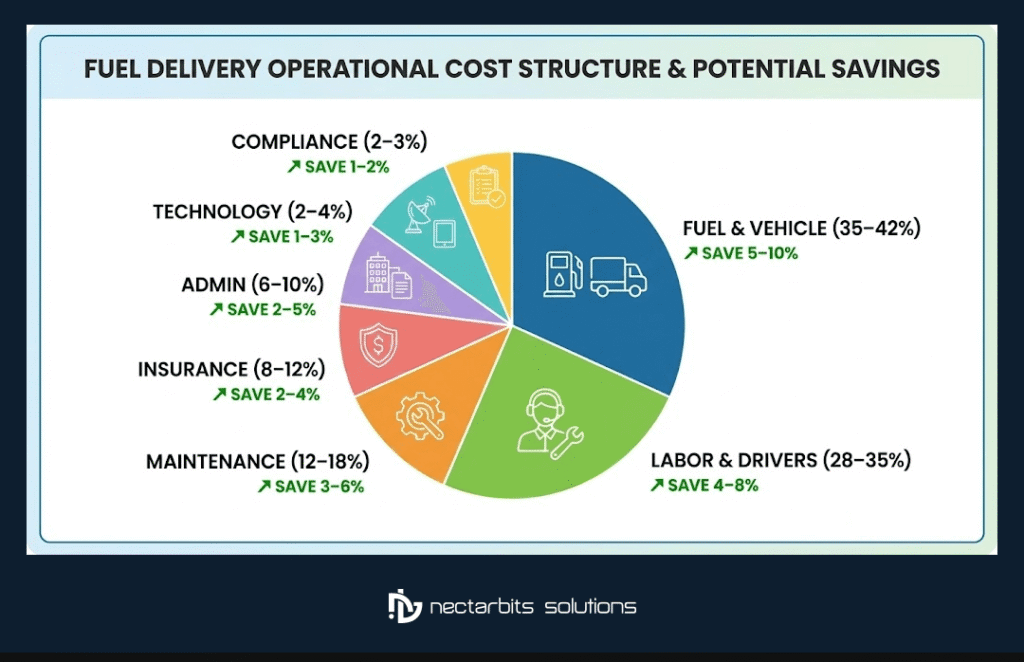

Tech Solution 1: AI-Powered Route Optimization

The Hidden Cost of Inefficient Routing

Route inefficiency represents one of the largest opportunities to reduce fuel delivery costs. Traditional routing methods—whether manual planning or basic GPS navigation—fail to account for the complex variables affecting fuel delivery efficiency.

Traditional Routing Costs:

- Average 22-35% excess mileage compared to optimal routes

- 15-25 minutes wasted per delivery due to poor sequencing

- $0.58 per mile operating cost (American Transportation Research Institute)

- 18% higher fuel consumption from suboptimal routing

AI Route Optimization Impact:

| Metric | Before AI Optimization | After AI Optimization | Improvement |

| Daily Miles (10-vehicle fleet) | 2,200 miles | 1,650 miles | -25% |

| Deliveries Per Day | 125 | 165 | +32% |

| Fuel Cost Per Mile | $0.85 | $0.72 | -15% |

| Driver Hours | 92 hours | 78 hours | -15% |

| Annual Fuel Savings | Baseline | $187,000 | N/A |

| Annual Labor Savings | Baseline | $124,000 | N/A |

How AI Route Optimization Works

Modern fuel delivery app development integrates advanced AI algorithms that:

Multi-Variable Optimization:

- Real-time traffic patterns: Predictive analysis, not just current conditions

- Historical delivery times: Learn from past performance

- Customer time windows: Balance preferences with efficiency

- Vehicle capacity constraints: Optimal load distribution

- Driver schedules and breaks: Regulatory compliance built in

- Fuel prices by location: Route to lower-cost fueling stations

- Weather conditions: Adjust for safety and efficiency

- Road restrictions: Account for weight limits, hazmat routes

Dynamic Re-Optimization:

- Continuous route adjustment as conditions change

- Urgent order insertion without disrupting the entire schedule

- Failed delivery rescheduling with minimal impact

- Real-time driver communication of route changes

ROI Timeline: AI route optimization typically delivers positive ROI within 4-7 months, with annual savings of $125,000-$400,000 for medium-sized operations.

Tech Solution 2: Automated Dispatch and Scheduling Systems

The Cost of Manual Dispatching

Manual dispatch operations create hidden costs that drain profitability:

Manual Dispatch Inefficiencies:

- 45-90 minutes daily spent on dispatch planning

- 12-18% scheduling errors requiring rework

- Poor load balancing across fleet (some vehicles 40% utilized, others 90%)

- Delayed response to urgent orders (average 45-minute lag)

- Limited visibility into driver location and status

- Communication overhead: 30-50 daily phone calls/texts per dispatcher

Automated Dispatch Benefits:

| Function | Manual Process Time | Automated Process Time | Time Saved |

| Order Assignment | 8-12 minutes | 15 seconds | 97% |

| Route Planning | 35-45 minutes | 2 minutes | 95% |

| Customer Communication | 15-25 minutes | Automated | 100% |

| Driver Check-ins | 20-30 minutes | Real-time auto | 100% |

| Schedule Adjustments | 10-20 minutes | 1 minute | 95% |

Automated Dispatch Capabilities

A comprehensive custom software development company can build dispatch automation that includes:

Intelligent Order Assignment:

- Automatic matching of orders to optimal vehicles

- Load optimization to maximize capacity utilization

- Priority-based scheduling (emergency, same-day, scheduled)

- Customer preference integration (favorite driver, time windows)

Real-Time Fleet Visibility:

- Live GPS tracking of all vehicles

- Delivery status updates (en route, arrived, completed)

- Estimated arrival times are automatically communicated to customers

- Exception alerts (delays, issues, emergencies)

Performance Analytics:

- On-time delivery percentage tracking

- Driver efficiency metrics and benchmarking

- Customer satisfaction scores integration

- Cost per delivery calculation and trending

Cost Savings: Automated dispatch reduces administrative labor by 60-75% and improves fleet utilization by 25-35%, generating annual savings of $85,000-$165,000 for mid-sized operations.

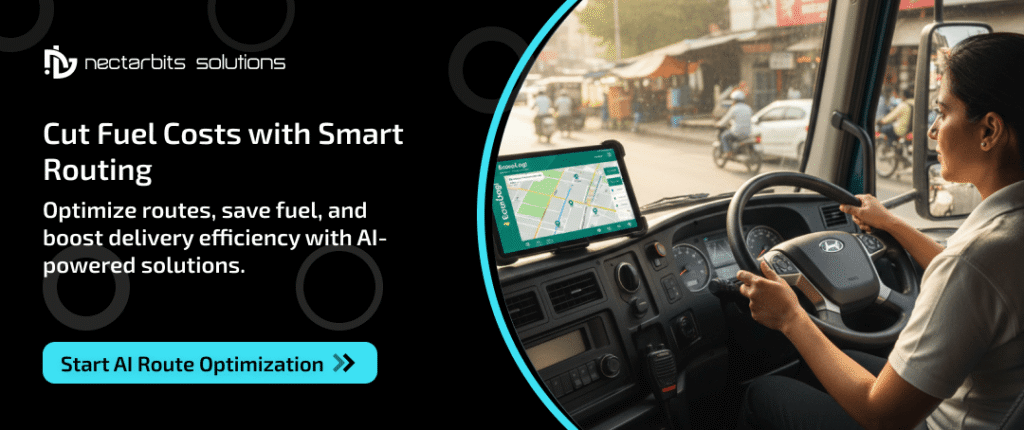

Tech Solution 3: Predictive Maintenance and Fleet Management

The True Cost of Reactive Maintenance

Reactive maintenance, fixing vehicles only after breakdowns, devastates operational efficiency, fuel delivery:

Reactive Maintenance Costs:

- Average breakdown cost: $3,500-$8,000 per incident (parts + labor + downtime)

- Lost revenue during downtime: $1,200-$2,500 per day per vehicle

- Emergency towing and service: $500-$1,500 per incident

- Customer service failures: Lost contracts, damaged reputation

- Cascading schedule disruption: Other vehicles must cover failed deliveries

Industry Data: Fleets using reactive maintenance experience 250% higher total maintenance costs than those using predictive approaches

Predictive Maintenance Technology

How Predictive Maintenance Reduces Fuel Delivery Costs:

| Maintenance Approach | Cost Per Mile | Unplanned Downtime | Vehicle Lifespan | Annual Cost (10 vehicles) |

| Reactive (Fix When Broken) | $0.22 | 8-12 days/year | 6-8 years | $198,000 |

| Preventive (Scheduled) | $0.16 | 3-5 days/year | 8-10 years | $144,000 |

| Predictive (Data-Driven) | $0.11 | 0.5-1.5 days/year | 10-12 years | $99,000 |

| Savings vs. Reactive | -50% | -90% | +40% | $99,000/year |

Predictive Maintenance Components:

IoT Sensor Integration:

- Engine diagnostics: Real-time performance monitoring

- Tire pressure sensors: Prevent blowouts and improve fuel efficiency

- Brake wear indicators: Schedule replacement before failure

- Fluid level monitors: Oil, coolant, hydraulic fluid tracking

- Battery health sensors: Prevent unexpected failures

AI-Powered Failure Prediction:

- Pattern recognition in sensor data identifies pre-failure indicators

- Maintenance scheduling optimization based on actual condition, not arbitrary mileage

- Parts inventory management ensures availability before needed

- Vendor coordination for scheduled service appointments

Fleet Management Dashboard:

- Vehicle health scores for the entire fleet

- Upcoming maintenance alerts with priority ranking

- Cost tracking per vehicle and fleet-wide

- Compliance documentation is automatically maintained

Implementation Partner: Working with an experienced on-demand delivery app development provider ensures seamless integration of predictive maintenance with dispatch and routing systems.

Tech Solution 4: Digital Customer Engagement and Self-Service

Administrative Cost Reduction Through Automation

Customer service and order management represent significant operational overhead that technology can dramatically reduce:

Traditional Customer Service Costs:

- Customer service staff: $45,000-$65,000 per full-time employee

- Phone system and communications: $8,000-$15,000 annually

- Order processing time: 8-12 minutes per order

- Order errors requiring rework: 8-15% of orders

- Payment processing inefficiency: Manual reconciliation, delayed payment

Digital Self-Service Impact:

| Function | Traditional Cost | Digital Cost | Savings |

| Order Processing | $8.50 per order | $0.35 per order | -96% |

| Customer Communication | $3.20 per interaction | $0.15 per interaction | -95% |

| Payment Processing | $2.75 per transaction | $0.45 per transaction | -84% |

| Account Management | $125/customer/year | $18/customer/year | -86% |

Digital Customer Platform Features

A well-designed mobile app design company creates customer platforms that reduce operational costs while improving satisfaction:

Customer Self-Service Portal:

- Online ordering: 24/7 order placement without staff intervention

- Automatic reordering: Tank monitoring triggers orders at optimal levels

- Real-time tracking: GPS-based delivery tracking reduces “where is my delivery” calls

- Digital invoicing and payment: Automated billing and instant payment processing

- Order history and analytics: Customers access past orders, usage patterns

Automated Customer Communication:

- Order confirmation: Instant automated email/SMS

- Delivery notifications: “Driver is 15 minutes away” alerts

- Delivery completion: Digital receipt with proof of delivery photo

- Proactive updates: Weather delays, schedule changes communicated automatically

Cost Impact: Digital customer engagement reduces customer service costs by 65-80%, representing annual savings of $55,000-$95,000 for operations with 500+ active customers.

Tech Solution 5: Real-Time Inventory and Tank Monitoring

Eliminating Emergency Deliveries and Stockouts

Emergency deliveries and inventory inefficiencies create disproportionate costs:

Emergency Delivery Costs:

- Premium pricing inability: Can’t charge enough to cover true cost

- Route disruption: Pulls vehicles from efficient scheduled routes

- Overtime labor: Often requires after-hours delivery

- Customer dissatisfaction: Even with emergency service, the customer experienced a stockout

- True cost: 3-5x more expensive than scheduled delivery

Inventory Inefficiency Costs:

- Overstocking: Capital tied up, storage costs, potential spoilage

- Understocking: Lost sales, emergency delivery costs

- Poor forecasting: Suboptimal purchasing and routing

IoT Tank Monitoring Technology

Automated Monitoring System:

| Metric | Manual Monitoring | IoT Monitoring | Impact |

| Monitoring Frequency | Weekly/Monthly | Real-time continuous | 168x-720x more data |

| Stockout Rate | 8-12% of customers/year | 0.1-0.5% | -96% |

| Emergency Deliveries | 15-22% of deliveries | 1-3% | -85% |

| Inventory Optimization | 65% efficiency | 94% efficiency | +45% |

| Administrative Time | 12 hrs/week | 0.5 hrs/week | -96% |

Tank Monitoring Features:

- Ultrasonic level sensors: Accurate measurement regardless of fuel type

- Consumption pattern analysis: AI predicts refill needs

- Automatic order generation: Orders are created when the optimal level is reached

- Weather integration: Adjust predictions for temperature impacts

- Historical analytics: Improve forecasting accuracy over time

Delivery Optimization Benefits:

- Route consolidation: Schedule multiple nearby customers on the same route

- Optimal delivery timing: Fill trucks, minimize partial loads

- Predictable scheduling: Customers know approximate delivery dates

- Dynamic pricing: Offer discounts for flexible timing

ROI Analysis: IoT tank monitoring systems reduce emergency deliveries by 85% and improve inventory turns by 35%, saving $75,000-$145,000 annually for operations with 300+ monitored tanks.

Tech Solution 6: Integrated Business Intelligence and Analytics

Data-Driven Decision Making

Without comprehensive analytics, fuel delivery operators make decisions based on intuition rather than data—often with costly results:

Decisions Requiring Data:

- Pricing strategy: What margins are sustainable per customer segment?

- Route profitability: Which geographic areas generate profit vs. loss?

- Customer profitability: Which customers are worth keeping vs. firing?

- Fleet sizing: Do you need more/fewer vehicles?

- Driver performance: Who excels and who needs improvement/replacement?

- Service offerings: Which products/services drive profitability?

Business Intelligence Dashboard

Key Performance Indicators (KPIs) to Track:

| Category | Critical Metrics | Target Benchmarks | Action Triggers |

| Operational Efficiency | Cost per delivery, Deliveries per vehicle/day | <$45/delivery, >12 deliveries/day | >$55/delivery: investigate routes |

| Fleet Performance | MPG, Utilization %, Downtime | >8 MPG, >75% utilization | <70% utilization: reduce fleet size |

| Customer Metrics | Lifetime value, Acquisition cost, Churn rate | >$15K LTV, <$800 CAC, <8% churn | >12% churn: service quality issue |

| Financial Health | Gross margin, Operating margin, ROI | >28% gross, >8% operating | <5% operating: immediate action |

| Driver Performance | On-time %, Fuel efficiency, Safety score | >95%, Within 5% fleet avg, Zero incidents | <90% on-time: retraining needed |

Analytics-Driven Cost Reduction Examples:

Example 1 – Route Profitability Analysis

- Discovery: Deliveries beyond a 45-mile radius averaged $72 cost vs. $68 revenue

- Action: Implemented a $15 long-distance surcharge and minimum order requirements

- Result: Long-distance deliveries became profitable OR customers consolidated orders (both positive outcomes)

- Annual Impact: $47,000 increased margin

Example 2 – Customer Profitability Segmentation

- Discovery: 18% of customers generated negative margins (high service costs, small orders, payment delays)

- Action: Implemented minimum order sizes, prepayment requirements, or service fee for small orders

- Result: 60% of unprofitable customers became profitable, 40% churned (acceptable)

- Annual Impact: $83,000 improved profitability

Example 3 – Driver Performance Optimization

- Discovery: Top-quartile drivers delivered 28% more efficiently than bottom-quartile drivers

- Action: Implemented performance-based bonuses and targeted training for low performers

- Result: Fleet-wide efficiency improved 14%

- Annual Impact: $96,000 savings

Implementation Roadmap: Your Path to Reduce Fuel Delivery Costs

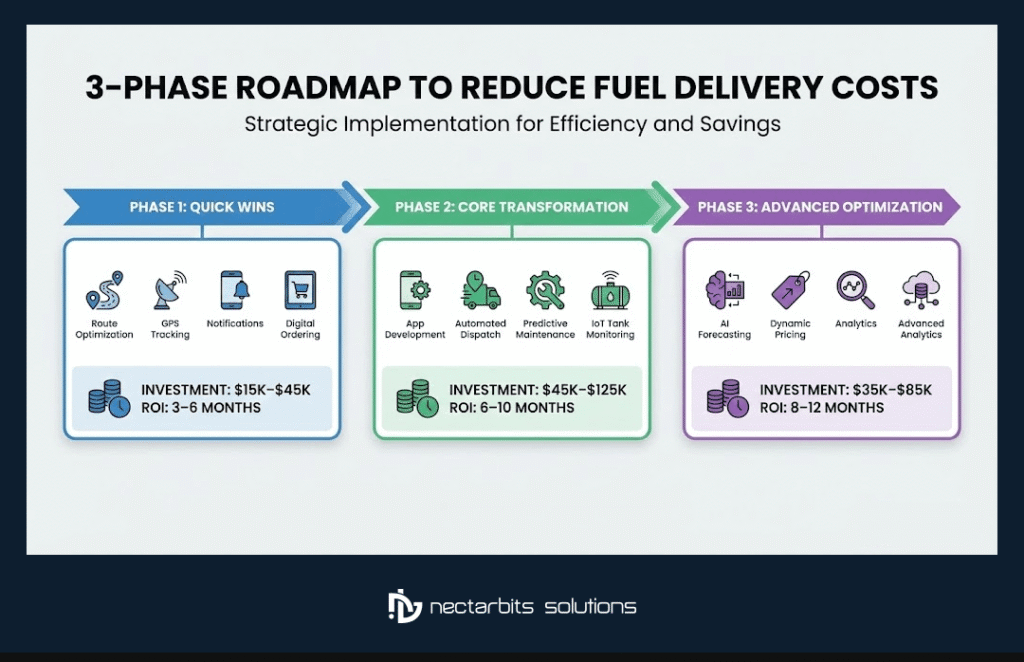

Phase 1: Quick Wins (Months 1-3)

Investment: $15,000 – $45,000

Expected Savings: $35,000 – $75,000 in Year 1

ROI: Positive within 3-6 months

Immediate Actions:

- Implement basic route optimization software

- Deploy GPS tracking across the fleet

- Set up automated customer notifications

- Create a basic performance dashboard

- Digitize order intake (online ordering)

Quick Win Impact Table:

| Initiative | Implementation Cost | Monthly Savings | Payback Period |

| Route Optimization | $8,000 | $4,200 | 1.9 months |

| GPS Tracking | $3,500 | $1,800 | 1.9 months |

| Automated Notifications | $2,000 | $2,100 | 0.95 months |

| Digital Ordering | $6,000 | $3,400 | 1.8 months |

Phase 2: Core Transformation (Months 4-9)

Investment: $45,000 – $125,000

Expected Savings: $125,000 – $285,000 in Year 1

ROI: Positive within 6-10 months

Major Initiatives:

- Full fuel delivery app development with customer and driver apps

- Automated dispatch system integration

- Predictive maintenance platform deployment

- IoT tank monitoring for the top 100 customers

- Business intelligence dashboard launch

Phase 3: Advanced Optimization (Months 10-18)

Investment: $35,000 – $85,000

Expected Savings: $95,000 – $185,000 annually (ongoing)

ROI: Positive within 8-12 months

Advanced Features:

- AI-powered demand forecasting

- Dynamic pricing engine

- Complete IoT tank monitoring fleet-wide

- Advanced analytics and ML insights

- Integration with accounting/ERP systems

Total Investment and Return Analysis

18-Month Implementation:

| Phase | Investment | Year 1 Savings | Year 2+ Annual Savings | Cumulative 3-Year ROI |

| Phase 1 | $25,000 | $55,000 | $75,000 | 880% |

| Phase 2 | $85,000 | $205,000 | $285,000 | 925% |

| Phase 3 | $60,000 | $140,000 | $185,000 | 825% |

| TOTAL | $170,000 | $400,000 | $545,000/year | 860% |

Read more: Real case study on reducing fleet downtime and costs through smart technology in our detailed analysis of Filld’s on-demand fleet fueling transformation.

Overcoming Implementation Challenges

Challenge 1: We Can’t Afford the Technology Investment

Reality Check: You can’t afford NOT to invest.

Solution: Phased implementation spreads costs while generating savings that fund subsequent phases. Phase 1 quick wins ($25,000 investment) generate $55,000 Year 1 savings—use this to fund Phase 2 with zero net capital required.

Alternative Funding:

- SaaS pricing models: Monthly subscriptions instead of high upfront costs

- ROI-based financing: Technology vendors offering payment terms tied to savings

- Operational budget reallocation: Reduce spending on inefficient processes to fund technology

Challenge 2: Our Team Will Resist Change

Solution: Position technology as an employee enabler, not a replacement.

Change Management Best Practices:

- Involve staff in selection: Drivers and dispatchers test platforms, provide input

- Emphasize benefits to them: Less stress, fewer emergency calls, easier jobs

- Comprehensive training: Invest in proper onboarding (2-3 days minimum)

- Celebrate wins: Share savings achieved, thank the team for adoption

- Performance incentives: Bonus structure tied to efficiency metrics

Challenge 3: We Tried Technology Before, and It Didn’t Work

Root Cause Analysis: Previous failures typically stem from:

- Wrong technology selection: Chose based on price, not fit

- Poor implementation: Inadequate training, no change management

- Incomplete deployment: Partial rollout without full integration

- Vendor issues: Poor support, outdated technology

Solution: Partner with proven experts. A specialized custom software development company brings:

- Industry expertise: Understanding of fuel delivery-specific needs

- Custom development: Solutions tailored to your exact workflows

- Implementation support: Dedicated team through rollout

- Ongoing optimization: Continuous improvement, not set-and-forget

Measuring Success: KPIs That Matter

Cost Reduction Metrics

Track These Weekly:

| Metric | Calculation | Target Improvement | Industry Benchmark |

| Cost Per Delivery | Total operating cost ÷ Deliveries | -25% in 12 months | $38-$52 |

| Fuel Cost Per Mile | Fuel expense ÷ Total miles | -15% in 12 months | $0.65-$0.85 |

| Labor Cost Per Delivery | Driver wages ÷ Deliveries | -18% in 12 months | $12-$18 |

| Maintenance Cost Per Mile | Maintenance expense ÷ Total miles | -30% in 12 months | $0.09-$0.14 |

| Administrative Cost % | Admin expense ÷ Revenue | -50% in 12 months | 4-7% |

Operational Efficiency Metrics:

| Metric | Target | Technology Impact |

| Deliveries Per Vehicle Per Day | >12 | Route optimization +32% |

| Fleet Utilization Rate | >78% | Dispatch automation +25% |

| On-Time Delivery Percentage | >96% | Real-time tracking +18% |

| Emergency Delivery Rate | <2% | Tank monitoring -85% |

| Order Error Rate | <1% | Digital ordering -94% |

The Competitive Advantage of Operational Excellence

Beyond cost reduction, operational efficiency in fuel delivery creates strategic advantages:

Market Differentiation:

- Superior reliability: 96%+ on-time delivery vs. competitor 82%

- Customer convenience: 24/7 self-service ordering, real-time tracking

- Environmental responsibility: Route optimization reduces emissions 25%+

- Technology leadership: Modern, professional image attracts premium customers

Pricing Power:

- Value-based pricing: Premium service justifies premium pricing

- Customer retention: 89% vs. industry average 73%

- Lower acquisition cost: Referrals and reputation reduce marketing spend

- Margin expansion: Efficiency gains allow competitive pricing while maintaining margins

Scalability:

- Growth without proportional cost increase: Handle 40% more volume with the same fleet

- Geographic expansion: Efficient operations make new territories viable

- Service expansion: Foundation for adding products/services

Acquisition readiness: Efficient operations command premium valuations

Conclusion

Reducing fuel delivery costs is no longer about cutting corners—it’s about building smarter, more efficient operations. With rising fuel, labor, and insurance expenses squeezing already thin margins, technology-driven solutions offer a clear path forward.

From AI-powered route optimization to automated dispatch, predictive maintenance, and real-time analytics, the right digital investments can turn inefficiencies into measurable savings. Fuel delivery operators that act now won’t just survive margin pressure—they’ll build scalable, resilient businesses ready for long-term growth.

Related Reading

Want to see real-world proof of technology-driven cost reduction in fuel delivery?

Theory is valuable, but nothing beats concrete results. Read more: Real case study on reducing fleet downtime and costs through smart technology in our comprehensive analysis of how Filld revolutionized on-demand fleet fueling. Discover the specific technologies, implementation strategies, and measurable results that transformed their operations—insights you can apply to your business today. Access the complete Filld case study here →

Frequently Asked Questions:-

Q1: How much can we really reduce fuel delivery costs with technology?

Most fuel delivery operations reduce total operating costs by 35–45% within 18 months of implementing comprehensive technology solutions. Quick wins, such as route optimization and GPS tracking, can deliver 15–20% savings within just 3–6 months. The exact savings depend on your current efficiency level—less efficient operations typically see larger improvements.

Q2: What’s the minimum investment required to see meaningful cost reduction?

Phase 1 “quick wins” usually require an investment of $15,000–$45,000, delivering a positive ROI within 3–6 months. Even starting with basic tools like route optimization and GPS tracking (around $12,000) can generate $50,000–$75,000 in annual savings for a 10-vehicle fleet.

Q3: How long does technology implementation take?

– Quick wins: 2–6 weeks for basic route optimization and tracking

– Core transformation: 3–6 months for full app development and system integration

– Advanced features: Additional 3–4 months for AI/ML-driven automation

Most operations achieve 80% of potential savings within 9–12 months.

Q4: Will technology replace our employees?

Technology enhances productivity without replacing staff. It allows administrative employees to focus on customer success and growth initiatives, increases deliveries per driver through smarter routes without longer hours, eliminates repetitive manual tasks to improve job satisfaction, and supports business expansion that creates new roles.

Q5: What if we’re too small for expensive technology?

Modern SaaS solutions bring enterprise-level tools to small operators with affordable subscriptions ($200–$800/month), quick 2–4 week deployment, scalable costs, and cloud-based access—allowing even single-truck operators to achieve ROI with route optimization and digital ordering.